the drug product has already been created and packaged. All through an aseptic fill complete process, packaging factors and the drug product or service are sterilized ahead of getting mixed beneath sterile circumstances.

one. Just one contaminated unit ought to result in an investigation, which include thought of repeat media fill;

A vital overview in the groupings and their contents confirmed that we didn't have a certain document centered on the technology of sterile filling. When there have been files addressing aseptic practices and sterility assurance controls, there was nothing at all precise to your equipment and means of finding a product right into a sealed container–closure method. The filling procedure step has numerous specifications to generally be achieved, which include:

Media fills could be used To guage aseptic procedures used in the assembly of pre-sterilized factors also to qualify operators for aseptic procedures.

A different essential element of liquid bottle filling equipment is their hygienic style, which enormously decreases the hazards of contamination. Contaminants or impurities in pharmaceutical products and solutions can compromise their high quality and pose serious overall health challenges to individuals.

To start using the Biowelder® TC automated tube welder, an operator inserts the tube holders, the disposable blade as well as the TPE tubes and initiates the welding procedure by means of the contact screen.

Filtered compressed air and granules of the plastic materials conforming to a predetermined specification and known being suitable Using the product or service being loaded (generally polyethylene, polypropylene or polyethylene/polypropylene co-polymers) are supplied on the device.

Small bottles and centrifuge tubes are ideal for sample assortment, along with the integral tubing and protected silicone seal of Mycap® avoid contaminations and Bogus positives.

Multi Channel Customized techniques for just about any amount of channels click here around (24). Supplied in both Rotary or Linear dispense units. Independent dispensing parameters is usually personalized as essential with uncomplicated programming.

A notable innovation During this area is ApiJect's BFS container style and design, which introduces distinctive functions that even more enhance the safety and operation of pharmaceutical packaging.

Incorporate Mycap® to bottles and carboys utilized for freeze/thaw operations to substantially strengthen filling and draining by generating Each and every an aseptically shut process and liberating the method from the confines of biosafety cupboard.

Your little-scale batch will click here place the beverage's principle, method, packaging and logistics techniques for the examination so that you enter the full-scale output section with minimal hazard.

Opta® SFT aseptic tube connectors make it possible for quickly and reliable sterile link and fluid transfer concerning two pre-sterilized approach factors.

Usually, aseptic processing is employed when terminal sterilization just isn't feasible for manufacturing sterile medications. To this conclusion, aseptic processing starts with sterilizing the drug product or service, and its container and any closures, independently in advance of assembling these products alongside one another.

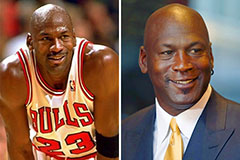

Michael Jordan Then & Now!

Michael Jordan Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!